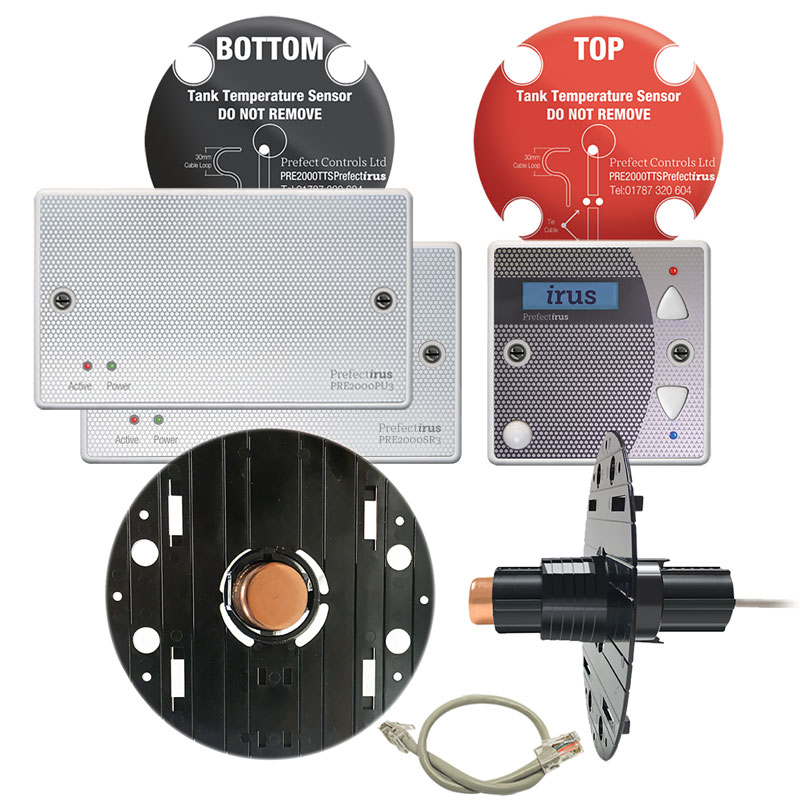

PRE2000W2-3

Twin element hot water tank kit

To see the product that has replaced this one click on this link.

Key features

- Top and bottom temperature sensors

- LV control Head

- Remote monitoring and control

- Autonomous control

- DUoS and TNUoS optimisation

- Leak detection sensor (optional)

- Measures RMS current

- 5-year warranty

Kit components:

- PRE2000CU3 Control head unit

- PRE2000PU3 Power unit

- PRE2000SR3 Slave Relay

- PRE2000TTS-TR Top temperature sensor

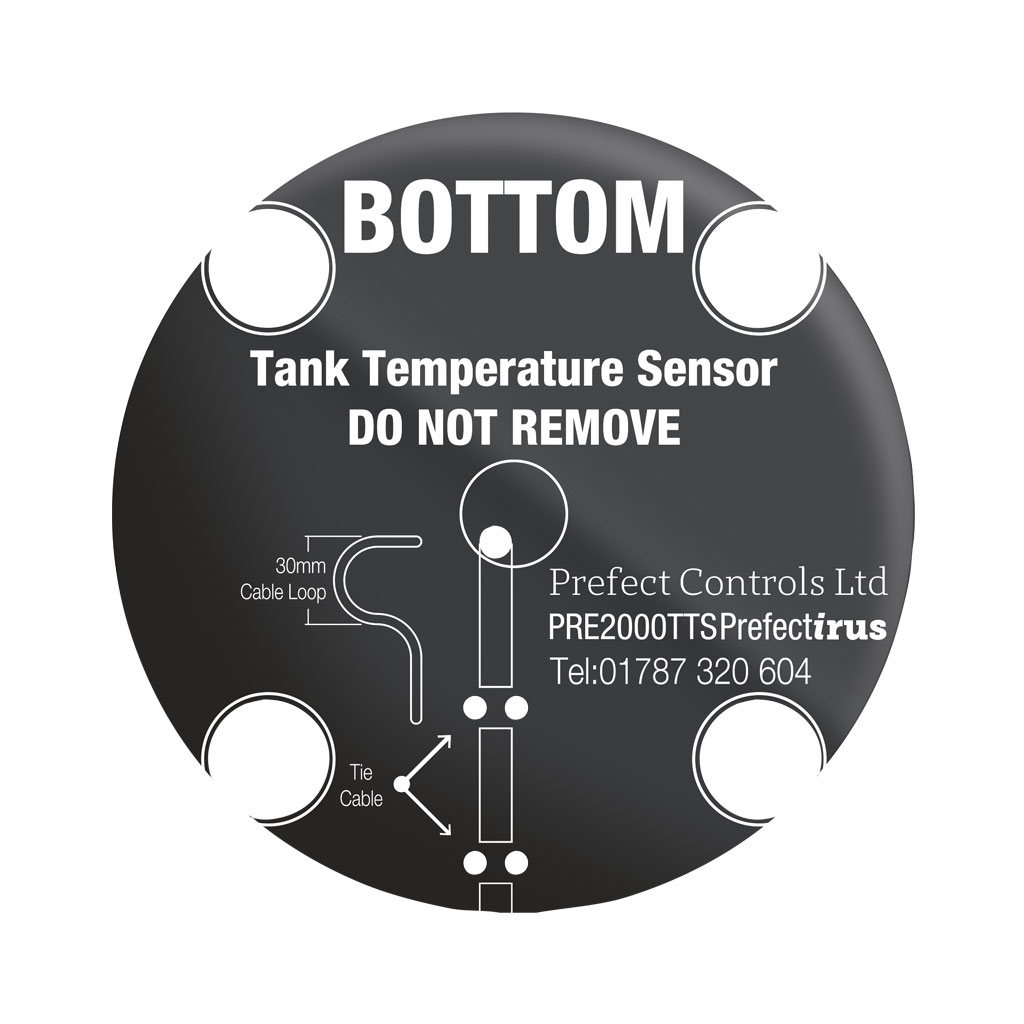

- PRE2000TTS-BB Bottom temperature sensor

- 300mm patch-lead

Requires Heat Paste

The Prefect Irus PRE2000W2-3 is a complete kit of components for connecting a twin element hot water tank system to the Prefect Irus control system.

The PRE2000CU3 is the control head unit and the control element of the kit. The head unit collects and stores data from the sensors and controls the PRE2000PU3 and PRE2000SR3 switching power to the elements.

The PRE2000PU3 power unit is the power supply for the low voltage head unit and the PRE2000SR3. The power unit houses a 16A relay for switching the 1st element when commanded by the head unit. The power unit uses mains borne signalling to transmit and receive data and commands between the head unit and Prefect Irus central control. Using the RJ45 connection, the PU3 connects the slave relay to the control head unit affording the use of a second relay.

The PRE2000SR3 slave relay is a secondary relay unit. The slave relay is connected by either a low voltage wiring connection or direct connection to the PU3 using the supplied 300mm RJ45 patch lead.

Once connected to the PU3 the slave relay can be directly controlled via the control head unit along side the PU3, the slave relay has a 16A relay output to control the second element.

The PRE2000TTS-TR & PRE2000TTS-BB are temperature sensors for hot water tanks with either a foam or metal jacket. The TR is the top temperature sensor coloured red for easy and reliable identification.The BB is the bottom temperature sensor coloured black. The sensors incorporate a copper contact and isolated pressure spring covered by an insulating foam sleeve.

1.25ml of thermal paste is applied to both copper contacts to thermally bond the sensors to the copper surface of the hot water tank providing an accurate and consistent temperature reading. The copper contact is forced onto the tank by a spring, the spring is thermally isolated and insulated so as not to corrupt temperature readings. A high tack adhesive 0.55mm polycarbonate overlay is then applied over the sensor opening, compressing the spring and forcing the contact onto the tank surface while resealing the insulating jacket.

Related Products

-

PRE2000MIFU2

Master interface unit -

PRE2000SIFU2

Secondary interface unit -

PRE2000W-3

Single element hot water tank kit -

PRE2000SEN

Water temperature sentinal -

PRE6000

13 Amp key switch connection unit -

PRE6001

13 Amp key switch connection unit -

PRE2000LDS

Leak detection sensor -

PRE2000ASOV

Cold-water inlet pipe auto shut off valve -

PRE2000WSO

Water shut-off unit